- 产品简介

-

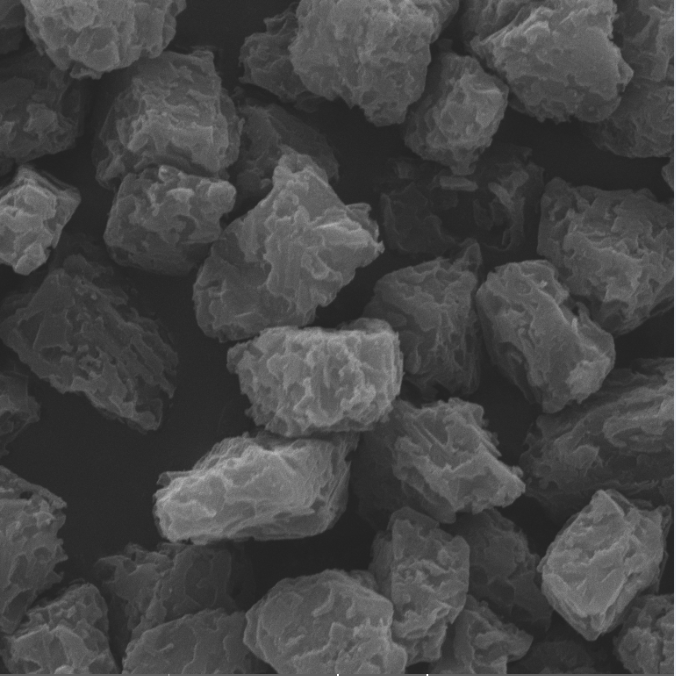

采用人工合成的优质单晶体金刚石为原料,强度高,磨削力强。

>>

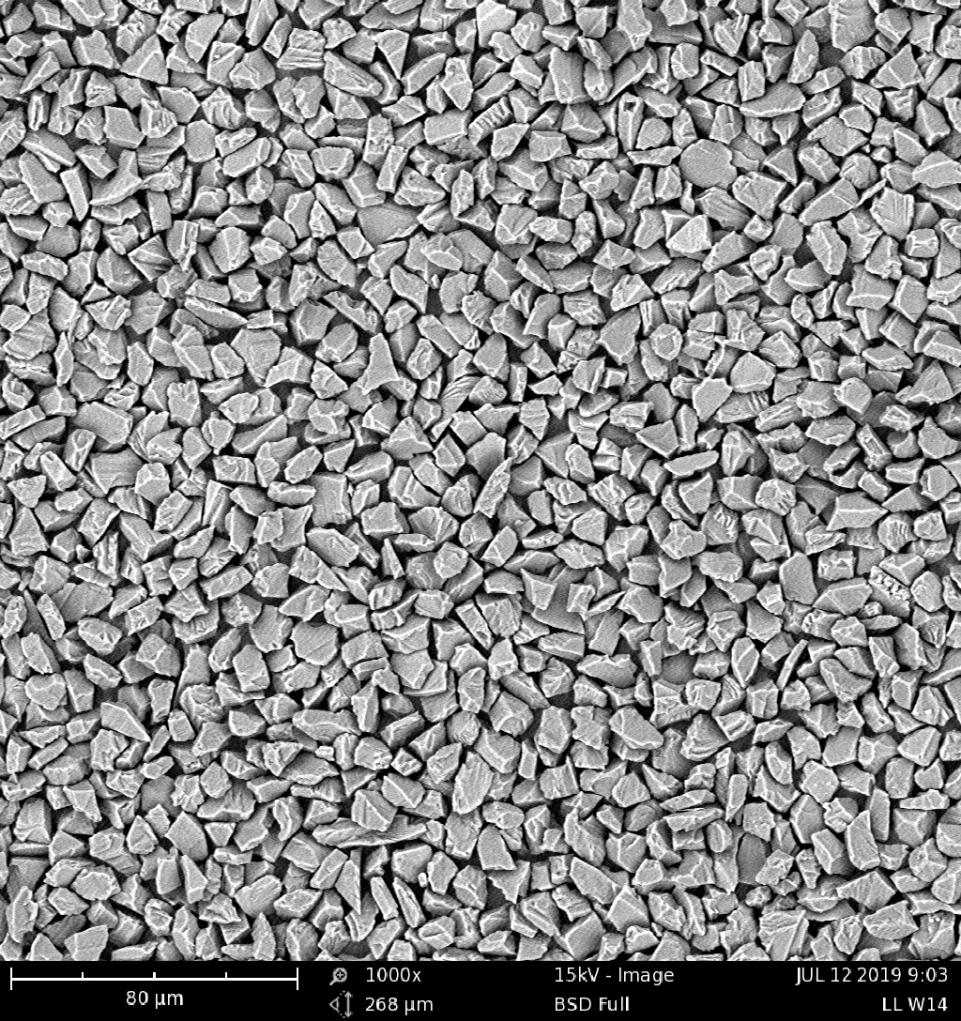

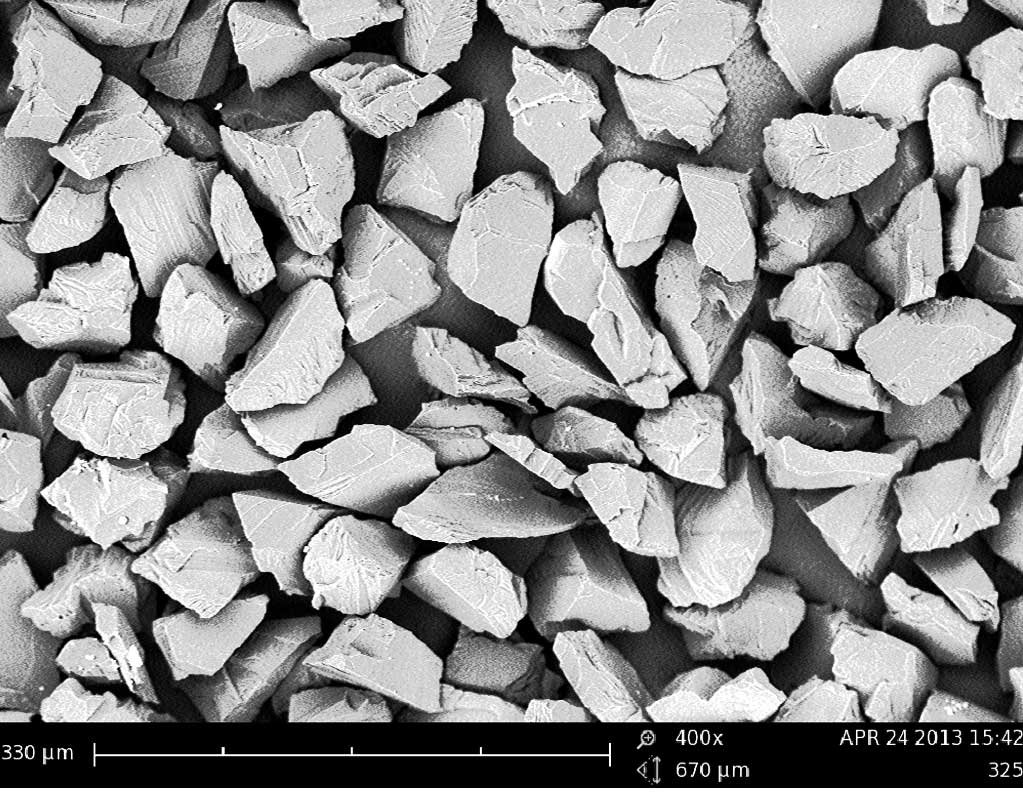

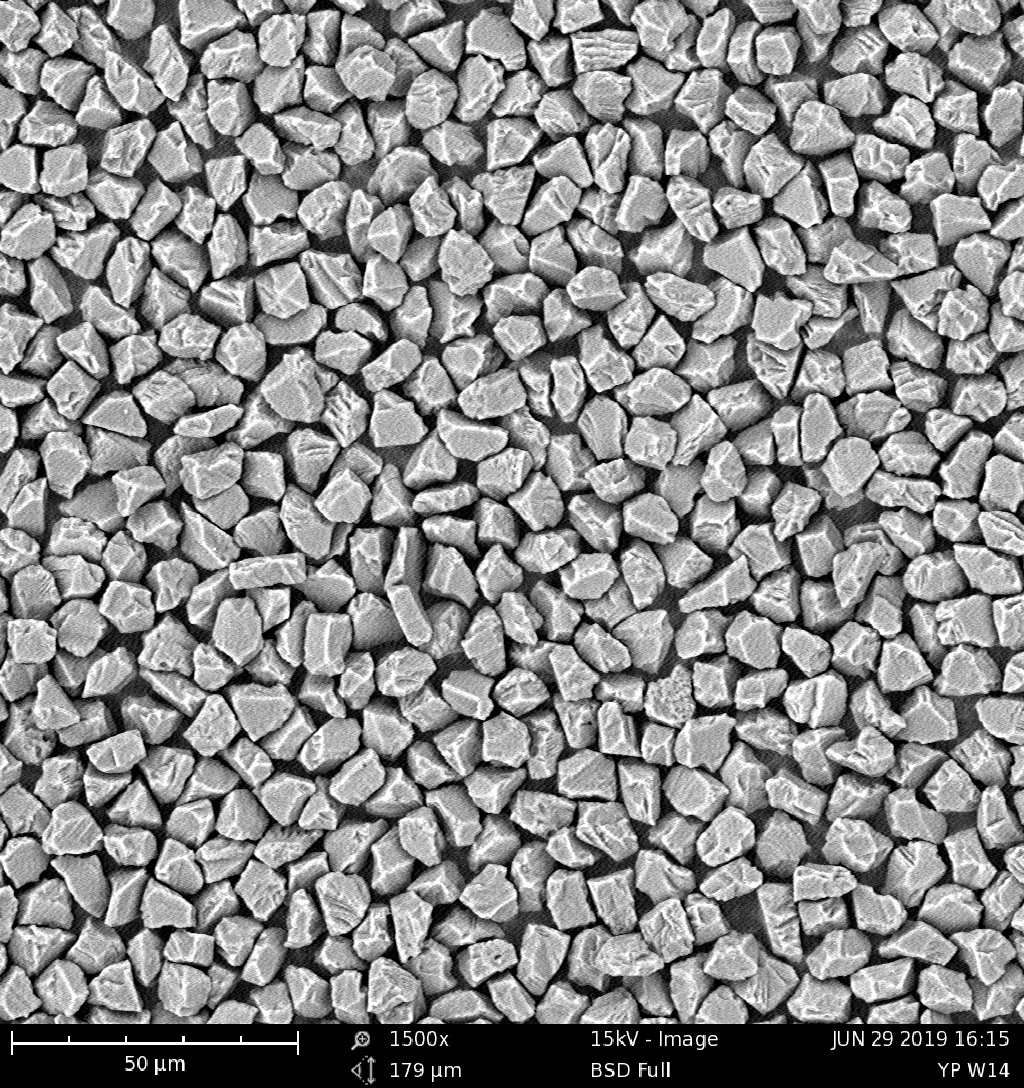

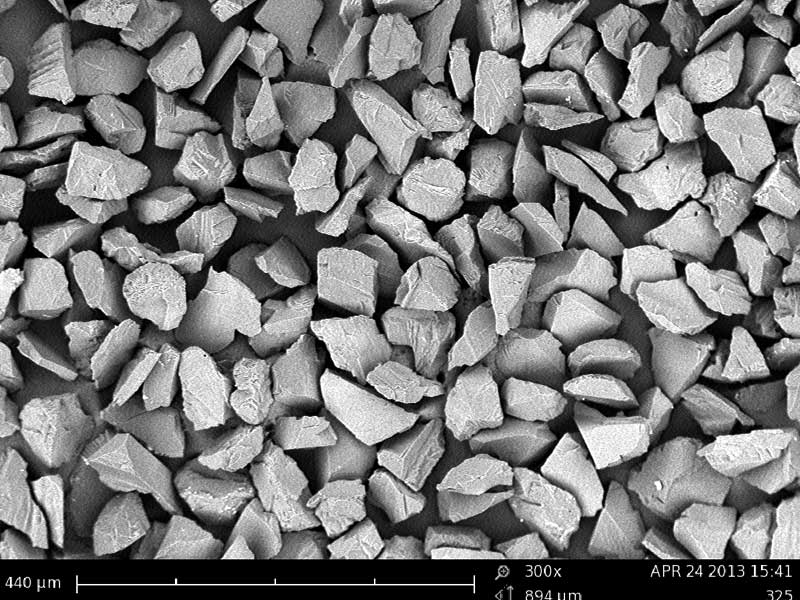

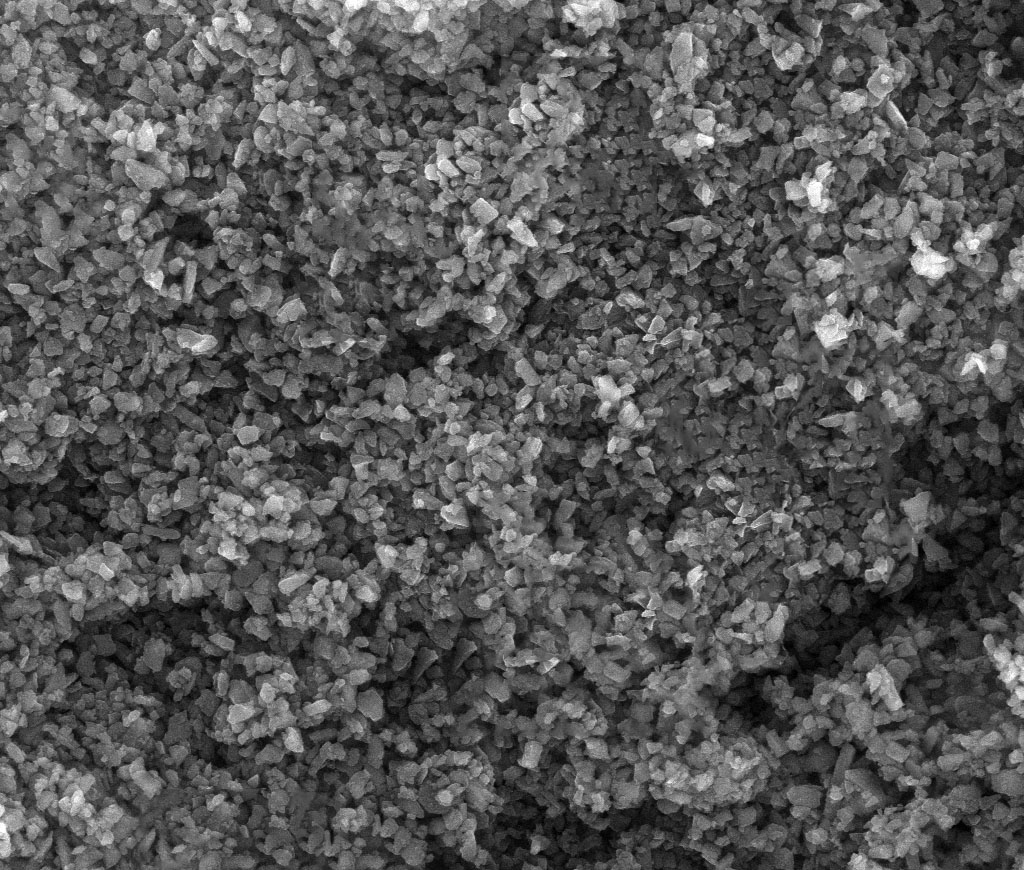

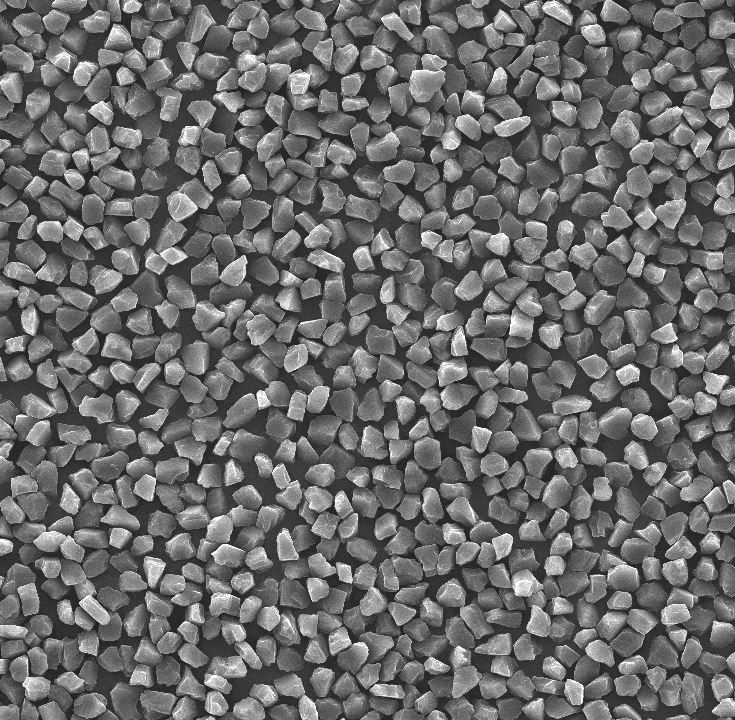

标准等级微粉 YLMD-S

产品特性:

a 颗粒均匀分布,粒度集中

b 晶型规则,严格控制针棒状及片状颗粒

c 杂质含量低

推荐用途:

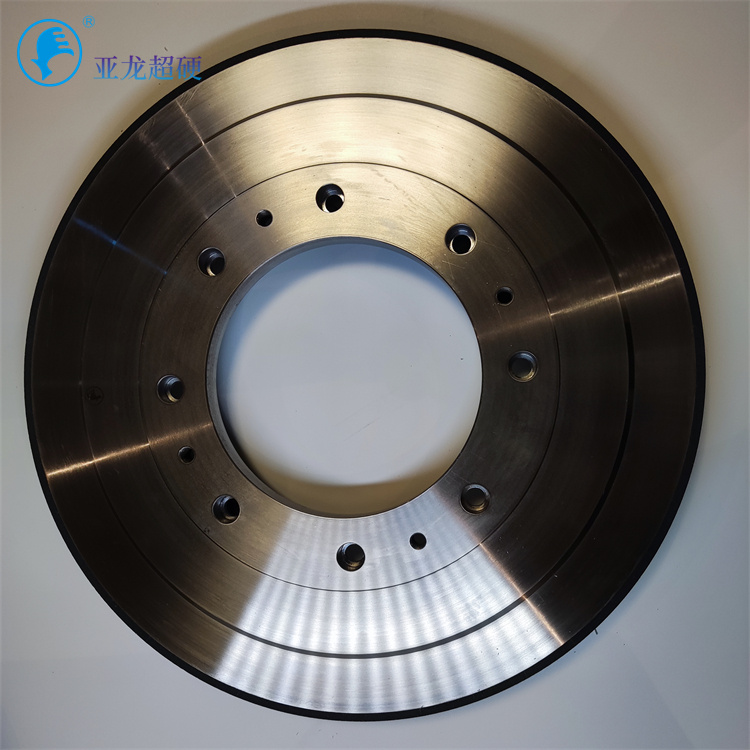

金属结合剂磨具、树脂结合剂磨具、刀具、陶瓷及光学玻璃等材质的研磨和抛光

| 粒度 Granularity (Micron) | 产品等级 Product Grade | ||

| 精微粉 PDM | 标准级微粉 SDM | 经济型微粉 EDM | |

| 120-140 | ○ | ○ | ○ |

| 100-120 | ○ | ○ | ○ |

| 80-100 | √ | √ | √ |

| 60-100 | ○ | ○ | ○ |

| 60-80 | ○ | ○ | ○ |

| 54-80 | ○ | ○ | ○ |

| 40-80 | ○ | ○ | ○ |

| 50-70 | ○ | ○ | ○ |

| 50-60 | √ | √ | √ |

| 40-60 | ○ | ○ | ○ |

| 30-60 | ○ | ○ | ○ |

| 36-54 | ○ | ○ | ○ |

| 40-50 | √ | √ | √ |

| 30-50 | ○ | ○ | ○ |

| 35-45 | ○ | ○ | ○ |

| 30-40 | √ | √ | √ |

| 20-40 | ○ | ○ | ○ |

| 22-36 | ○ | ○ | ○ |

| 25-30 | ○ | ○ | ○ |

| 20-30 | √ | √ | √ |

| 15-30 | ○ | ○ | ○ |

| 14-28 | √ | √ | √ |

| 20-25 | ○ | ○ | ○ |

| 15-25 | √ | √ | √ |

| 12-22 | ○ | ○ | ○ |

| 15-20 | ○ | ○ | ○ |

| 12-20 | ○ | ○ | ○ |

| 10-20 | √ | √ | √ |

| 12-17 | ○ | ○ | ○ |

| 10-16 | ○ | ○ | ○ |

| 10-15 | √ | √ | √ |

| 8-16 | √ | √ | √ |

| 8-15 | ○ | ○ | ○ |

| 7-14 | ○ | ○ | ○ |

| 8-12 | ○ | ○ | ○ |

| 6-12 | √ | √ | √ |

| 6-10 | ○ | ○ | ○ |

| 5-10 | √ | √ | √ |

| 5-9 | ○ | ○ | ○ |

| 6-8 | ○ | ○ | ○ |

| 5-8 | ○ | ○ | ○ |

| 4-8 | √ | √ | √ |

| 5-7 | ○ | ○ | ○ |

| 3.5-7 | √ | √ | √ |

| 4-6 | ○ | ○ | ○ |

| 3-6 | ○ | ○ | ○ |

| 2-6 | ○ | ○ | ○ |

| 3-5 | ○ | ○ | ○ |

| 2.5-5 | √ | √ | √ |

| 2-5 | √ | √ | √ |

| 2-4 | √ | √ | √ |

| 1.5-3.5 | √ | √ | √ |

| 2-3 | ○ | ○ | ○ |

| 1.5-3 | ○ | ○ | ○ |

| 1-3 | √ | √ | √ |

| 0.5-3 | ○ | ○ | ○ |

| 1.5-2.5 | √ | √ | √ |

| 1-2 | √ | √ | √ |

| 0-2 | √ | √ | √ |

| 0.5-1.5 | ○ | ○ | ○ |

| 0-1.5 | √ | √ | √ |

| 0.5-1 | ○ | ○ | ○ |

| 0-1 | √ | √ | √ |

| 0-0.5 | √ | √ | √ |

| 0-0.25 | √ | √ | √ |

| 0-0.2 | √ | √ | √ |

| 0-0.1 | √ | √ | √ |

√ 可供应的标准粒度

○ 可定制的粒度

中文

中文 English

English